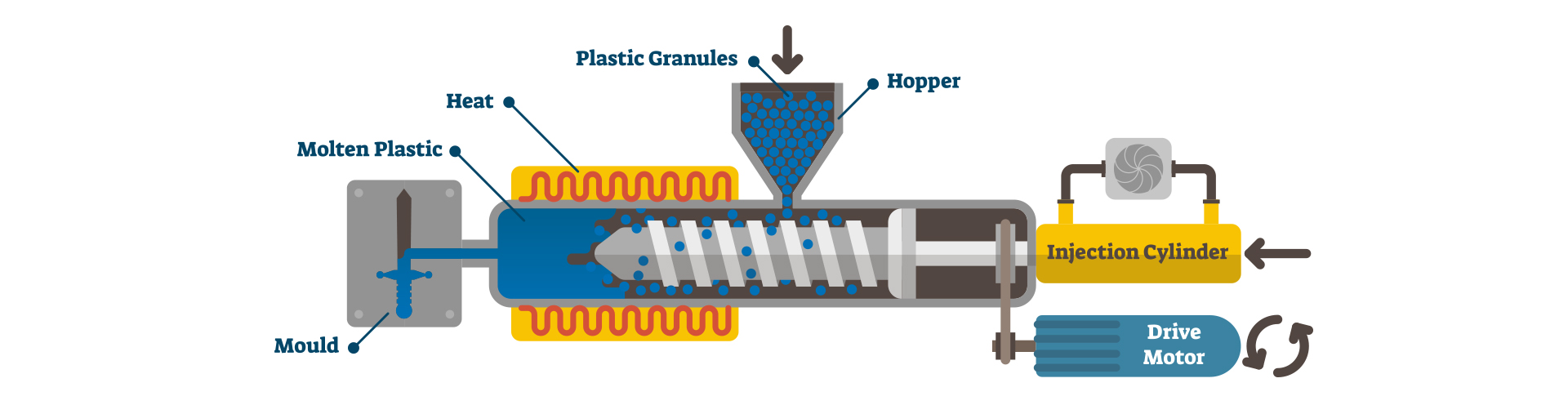

FULL-SERVICE CUSTOM INJECTION MOULDING

From start to finish, we offer full-service custom injection moulding, and it shows in everything we do.

WHAT WE PROVIDE:

18 500 Square Foot State-of-the-art Injection Moulding Facility - Privately Owned

Full Service Custom Injection Moulding Done On-site

Flexible Production Volumes - Small to Large Scale Production Runs

All Electric and Hydraulic Shibaura/Toshiba Presses - Press Tonnage Range from 160 - 500 Tons

Mould Variance 1oz to 50.6oz Shot Size

Various Mould Tooling Options

In-house Mould Testing and Trouble Shooting

Mould Repair and Refurbishing

Partnered with Tool and Die Specialists

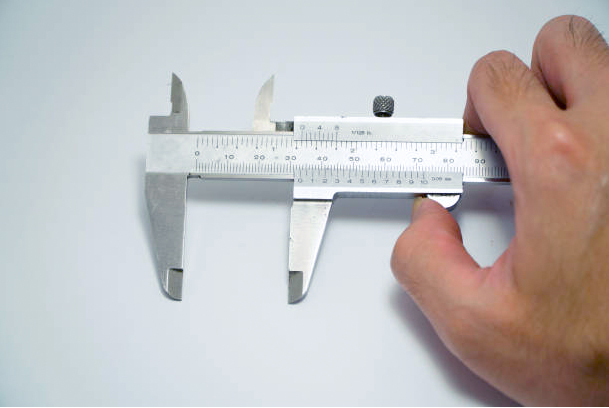

Strict Manufacturing Quality Controls and Standards

Experienced On-site Plastic Technologists

Sourcing for a Wide Range of Safe and Recyclable Resins and Engineered Thermoplastics

VALUE ADDED SERVICES:

3D Printing

Low Production Hot Stamping

Ultrasonic Welding

Light Assembly services

Packaging

Warehousing and Direct Shipping

MATERIALS & SOURCING

With over 50 years of supplier relationship development, we can help you acquire the best plastic material to get the job done right within your budget. We have established quick lead times with our local suppliers giving us the ability to manufacture samples using a wide variety of plastic compounds, and colour specifications.

We adhere to environmental and health standards and practices, and offer a wide range of recyclable and biodegradable materials.

PLASTIC INJECTION MOULDING MATERIALS:

ABS

ASA

Acrylic

HIPS

Engineered Thermoplastics

Enviro Friendly Biopolymers

PHA

PLA

Wood Infused Resins

Nylon

Polypropylene

Polycarbonate

Polyethylene

Polystyrene

SAN

TPV

TPE

INJECTION MOULDS

Full Service Custom Injection Moulding

When your job is too important to send offshore, trust T&T to get your injection mould tooling engineered with precision.

Our injection mould tooling is designed and manufactured to optimize immediate and long-term efficiency.

We are in partnerships with tool and die specialists that are committed to designing and manufacturing quality moulds that stand up to the rigorous demands of high-speed production.

TOOLING OPTIONS:

Multiple Cavity

Stacking Moulds

Thin Wall

Insert Moulding

Single & Double Core Pull

Multiple Airblow Systems

Hot Runner Tooling

Cold Runner Tooling

BUILT TO LAST

CONTACT US TO GET A QUOTE

Let us help you come up with the best solution for your custom injected moulded plastic products.

LOCATIONS SERVED: CANADA | USA | TORONTO | GTA | OAKVILLE | ONTARIO | QUEBEC | MANITOBA | MAINE | VERMONT | NEW YORK | MICHIGAN

Copyright ©2023 | T&T Custom Injection Moulding